LEELA PHARMA MACHINERIES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to LEELA PHARMA MACHINERIES

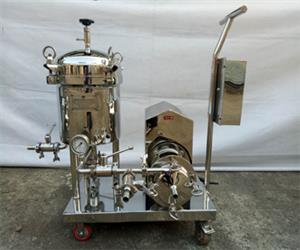

Sparkler Filter Press

wing to our expertise in this domain, we are involved in offering a broad range of Zero Holdup Filtration Unitto our clients spanning all over the country.

APPLICATION :

To filter final product in Pharmaceuticals, Perfumes, I. V. Fluids, Dyes & Chemicals, Activated carbon, Pesticides, Cosmetics, Varnishes, Polymers, Resins & Paints, Sugar syrup, Food, Plant Water Polishing, Fruit juice, Soft drink, Beer & Liquors, Edible & Non Edible oils.

SIZE AVAILABLE :

8” / 14” / 18” / 24” & 33” dia.

OPERATION :

The liquid to be filtered is forced in the chamber by the Transfer pump, where it finds its way to the top of the filter media of each plate through circular opening on the side of the plates.

Under pressure clear Liquid passes through the filter media leaving suspended particles on top of the filter.

The clear filtrate runs down through central channel formed by the interlocking cups and exists through the outlet valve.

FEATURES :

Single pass clear filtration.

Full batch recovery of the filtrate.

Easy install inside cartridge assembly.

Complete cake retains on the plate.

Uniform distribution of cake on each plate.

Reduce the cost of treatment of catalyst, Toxic Chemicals.

Less exposure to the operating person.

No contamination of the internal surface of the shell.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.